Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

모형: QD,QDY,QC,QZ,YZ,QB

상표: DGCrane

포장: 강철 구조물과 트롤리는 부직포로 포장됩니다.

생산력: 1000sets/month

수송: Ocean,Land

원산지: 중국

지원에 대한 지원: 12000 sets/year

인증 : ISO9001,ISO14001

HS 코드: 84261120

포트: Qingdao Port,Tianjin Port,Shanghai Port

지불 유형: L/C,T/T,Paypal,Western Union

인 코텀: FOB,CFR,CIF,EXW,FCA,CPT

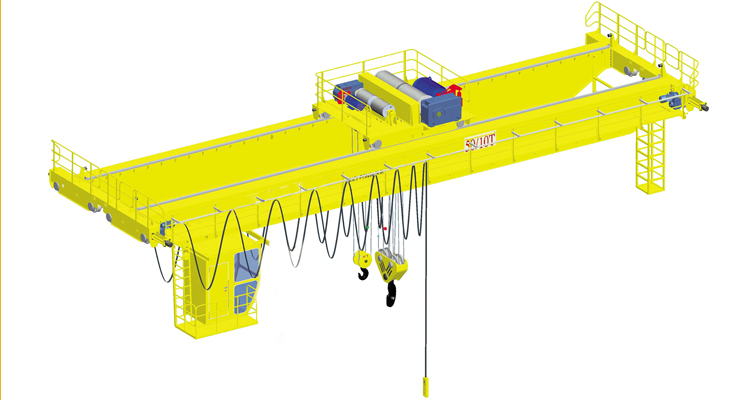

더블 대들보 모터 구동 식 오버 헤드 브리지 크레인 20ton에 대한 간략한 소개

이중 거더 브리지 크레인 (오버 헤드 크레인, eot 크레인)은 일반적인 창고 하역 및 자재 취급 작업을 수행하기 위해 열린 창고 또는 철도 옆에 적용되며 사용 빈도에 따라 A3 ~ A8의 작업 등급으로 나눌 수 있습니다.

이 교량 기중기 는 교량, 여행 기계 장치, 트롤리, 전기 장비로 이루어져 있고, 교량 구조는 상자에 의하여 용접 된 구조를 채택하고, 기중기 여행 기계 장치는 모터와 속도 흡진기를 가진 분리 된 드라이브를 채택합니다. 모든 메커니즘은 운전실에서 제어됩니다. 전원 공급 장치는 케이블 페스 툰과 슬라이딩 와이어를 채택하여 주문할 때 하나를 선택하십시오.

표준 리프팅 용량 : 5T, 10T, 16 / 3.2T, 20 / 5T, 32 / 5T, 50 / 10T, 75 / 20T, 100 / 20T, 100 / 30T, 125 / 30T, 150 / 30T, 160 / 32T, 200 / 50T, 400 / 80T, 550 / 250T, 더 큰 용량은 맞춤형 크기입니다.

교량 기중기 유형 :

|

LH Double Girder Bridge Crane

|

|

QD Double Girder Bridge Crane

|

|

QC Magnet Double Girder Bridge Crane

|

|

Ladle/foundry Bridge Crane

|

|

QZ Double Girder Grab Bridge Crane

|

|

|

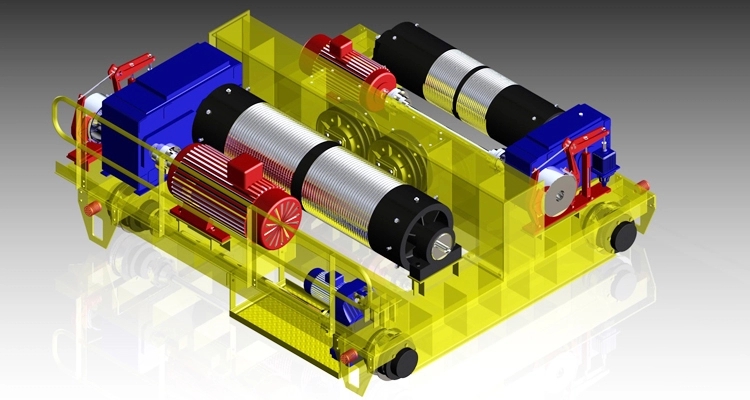

1. Motor Motor adopts YZR series crane special use winding rotor three-phoase asynchronous motor. YZR series motor is suitable for driving various kinds of hoisting machinery and metallurgy auxiliary equipment, with high overload capacity and mechanical strength, especially for short-term or intermittent operation, frequent start-up, braking and significant vibration and impact of equipment. Motor protection grade is IP54, insulation grade is F class. 2. Reducer All speed reducers in our company have installed oil receiving device to avoid the oil stain caused by oil change. The soft tooth surface reducer is the most advanced common structure design, with the steel plate welding, the gear is high quality low carbon alloy steel, widely used. 3. Brake Adopt YWZ series hydraulic brake, this series brake uses pusher as the actuator of the brake, electric hydraulic booster is a kind of integrated motor, centrifugal pump, oil cylinder, and very compact drive control device. Mainly used for mechanical braking of mechanical driving devices such as lifting transportation, metallurgy, mining, port and building. 4. Hook block It consists of hook and pulley. The hook material is DG34CrMo. The pulley material is Q235 hot-rolling. It adopts anti-friction roller bearing, the hook can be 360degree rotation. It is equipped with spring-pressed safety lock, preventing from slipping off. All pulleys use maintenance-free bearing, the design can efficiently prevent abrasion between steel rope and pulley shell. It has delicate overall structure and volume as well as nice appearance.

5. Coupling & Shaft Use safe, reliable transmission performance coupling to connect the various agencies of transmission components, torque transmission at the same time compensate for certain installation errors caused by the angle and radial offset to improve the dynamic characteristics of the transmission. Brake wheel coupling includes brake wheel and braking unit. The transmission shaft adopts 45# steel material, which is strictly calculated by strength (static strength and fatigue strength).Ensure its strength and reliability, and smooth the transmission torque. 6. Buffer and limit switch Trolley is installed JHQ polyurethane buffers, it has the good performance of absorbing the moving mechanism energy and reducing the impact. 7. Electric box

It is of IP55 protection class, air plug and fast-easy installation; Schneider/ABB/Siemens/CHINT electrical kits, etc. |

|

|

Incoming material test |

Every batch of raw materials must be tested when they enter the factory. We set up a special testing room.It covers non-destructive inspection room, metallographic analysis and hardness inspection room, mechanics inspection and chemical inspection room. Testing methods has non-destructive testing,metallographic analysis, mechanical testing and chemical analysis, mainly testing and control of the raw materials, crane components, product |

|

Uncoiling and flattening the steel plate |

After uncoiling, leveling, sizing and shearing, the required length and width of the flat sheet can be obtained, which can protect the flat sheet without scars, high shearing accuracy, double palletizing and discharging, high efficiency and speed. |

|

Cutting |

|

| Pressure Groove |

According to crane specifications to groove pressing with different model, and main girder forming at one time can realize that the U-groove of the whole main girder of single girder crane has no butt weld, thus reducing stress concentration point, improving the strength and stiffness of the main girder, and greatly improving the comprehensive bearing capacity of the main girder. |

| Welding Stiffener |

There is a support which can keep the main girder be not deformed, and workers can work easily without bending. |

| Welding main beam with the ending | |

| Welding I beam and ventral |

Submerged arc welding (SAW) is a kind of protective welding with Rohm double gun automatic welding, which has the advantages of full weld, deep molten pool, beautiful shape and high welding quality. At the same time, the welding distortion is reduced. |

| Checking span,welding flange |

In production, the hanging plates of the main girder and the end girder are processed together, punched together, and then knock down from end beam and weld to the main girder. |

| Painting |

Two-layer primer, two-layer paint |

| Steel parts | Steel parts are packed in polythene woven cloth, which can prevent rainwater from directly contacting the crane and protect the painting |

| Electric parts and hoist | Electric parts are packed by strong plywood crate case, which plays a protective and moistureproof role. |

|

| Basic informations needed of double girder bridge crane |

1. Capacity:_ ( max weight of material) 2. Span:_ ( rail center to rail center) 3. Lifting height:_ ( from ground to hook) 4. Crane traveling legnth:_ 5. What goods will the crane lift? 6. Working environment: 7. Speed requirement: 8. Comtrol method: control pendent, remote control, cabin control. |

제품 디렉토리 : 오버 헤드 크레인 > 두 배 대들보 교량 기중기

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.